The Cast:

Shawn is Senior Graphic Designer for EarthIntegrate, a leading provider of marketing technology with their relationship marketing platform, Pando. He is also an avid painter, hand-letterer, and letterpress enthusiast.

Jo is the Art Director for The Black Sheep Agency, a cause-driven marketing and branding firm. She is also a fan of antiques and an occasional restorer of found objects.

The Story:

Shawn: Jo first introduced me to the world of estatesales.net back in the beginning of 2015, and I signed myself up for their email list. After a couple of months of weeding through the various sales online, I came across one that had an old letterpress for sale. I’d been wanting a letterpress machine ever since my first digital design class back in college (circa 2006). Even then I knew that these machines cost thousands of dollars—way beyond my budget—but I had made a promise then to myself that I would eventually get one of my own.

Jo: I’ve been going to estate sales and antique stores for about twelve years, and NEVER had I seen a letterpress for sale at one. The occasional lead type, maybe, but never the whole press. It’s the job of companies that host estate sales to research and investigate the pieces in the estate before they price them for sale, so I told Shawn to forget about that press—they are EXPENSIVE, and that one, I thought, would probably be super overpriced.

Shawn: I was sort of deflated. I’d heard Jo tell me how expensive some of these items can be at estate sales and so I figured that this press would be no different. I figured the people running the sale HAD to know how much one of these old, vintage presses should cost.

Jo: The opening day of the estate sale, I had a breakfast meeting cancel and I decided to spend my spare time wisely… by heading into Houston early in the morning to check out the letterpress Shawn was wanting. I wasn’t optimistic, but I figured I’d go look, and maybe find some other stuff. I texted Shawn to keep a close eye on his phone in case the impossible happened and the press was A) still available, and B) cheap.

Shawn: I wasn’t feeling optimistic, and even joked that the press had to be over $1200, easily.

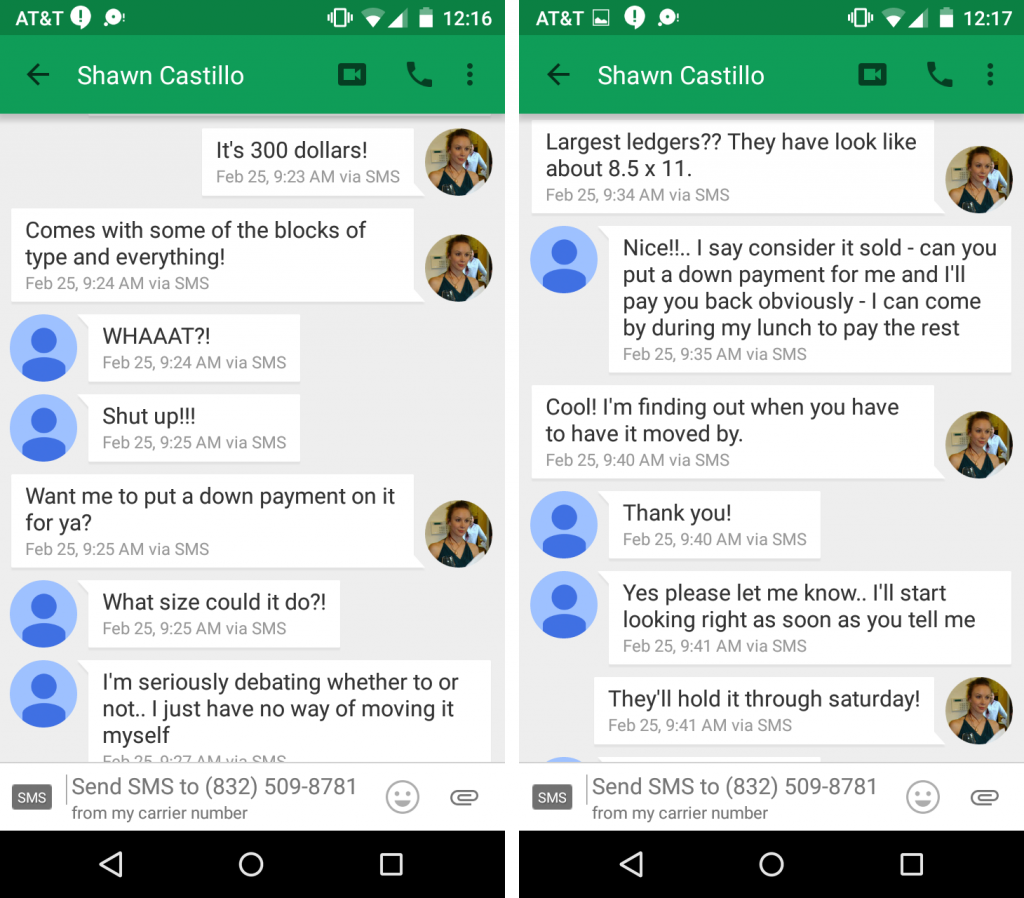

Jo: When I got there, the press appeared to be in really good condition with no rust, and the gears were turning freely. It even had some accessories, like extra chases, but no actual type. Best of all, it was priced at $300.00.

THREE. HUNDRED. DOLLARS.

I didn’t know then how much letterpresses sell for online, but that was CHEAP. The following string of texts ensued, the result being that I bought the letterpress on the spot for Shawn with a lot of people gathered around it like I was a crazy person.

Shawn: I was completely shocked what this press was going for! (Hence the “WHAAT?!” I texted in all caps.) Also, at the time this happened I was pretty strapped for cash so spending $300 on this press really left me broke, not to mention the cost of having it moved. I knew, though, that I would never again come across this kind of press, as cheap as it was, in my life. I just had to have it.

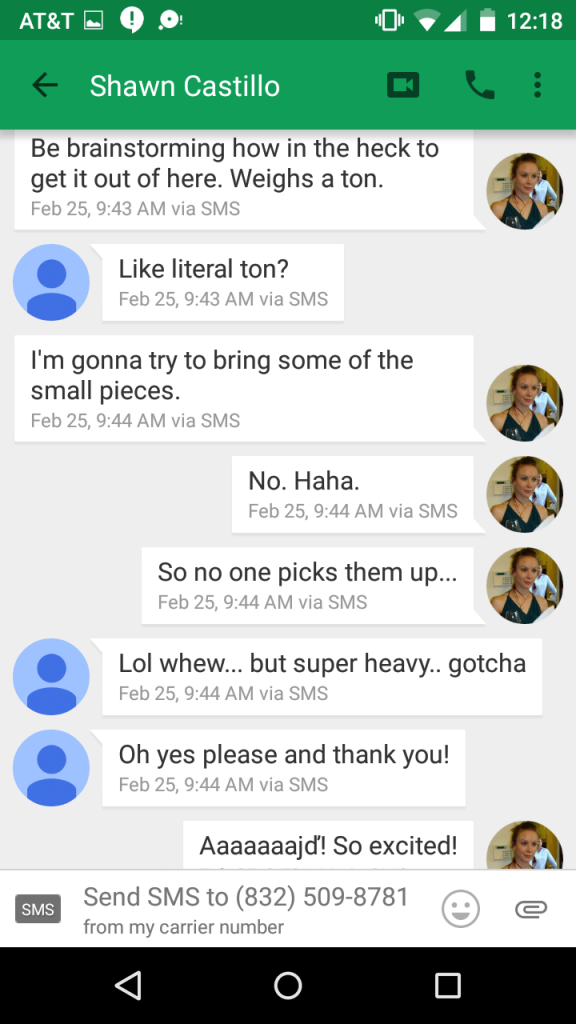

Jo: The next issue was the fact that the press weighed about 1000 pounds. This was the stage at which it became Shawn’s problem. 🙂

Shawn: Yeah, figuring out how to move the press proved to be a much bigger challenge than I expected. The press weighs an impressive 1,000 pounds. Initially, I tried reaching out to traditional furniture movers, but no one was equipped to deal with such a heavy item.

Luckily, I had taken a class at The Printing Museum about a year ago to learn digital letterpress printing. The instructor happened to be John Earles from Work Horse Print Shop. He’d been an excellent instructor, so I reached out to Mr. Earles to let him know about my recent purchase and the troubles I was having. He ended up putting me in touch with a super helpful guy with a hydraulic lift here in Houston that did the job that weekend. John also offered to show me personally all the ins and outs of maintaining a working letterpress printing machine.

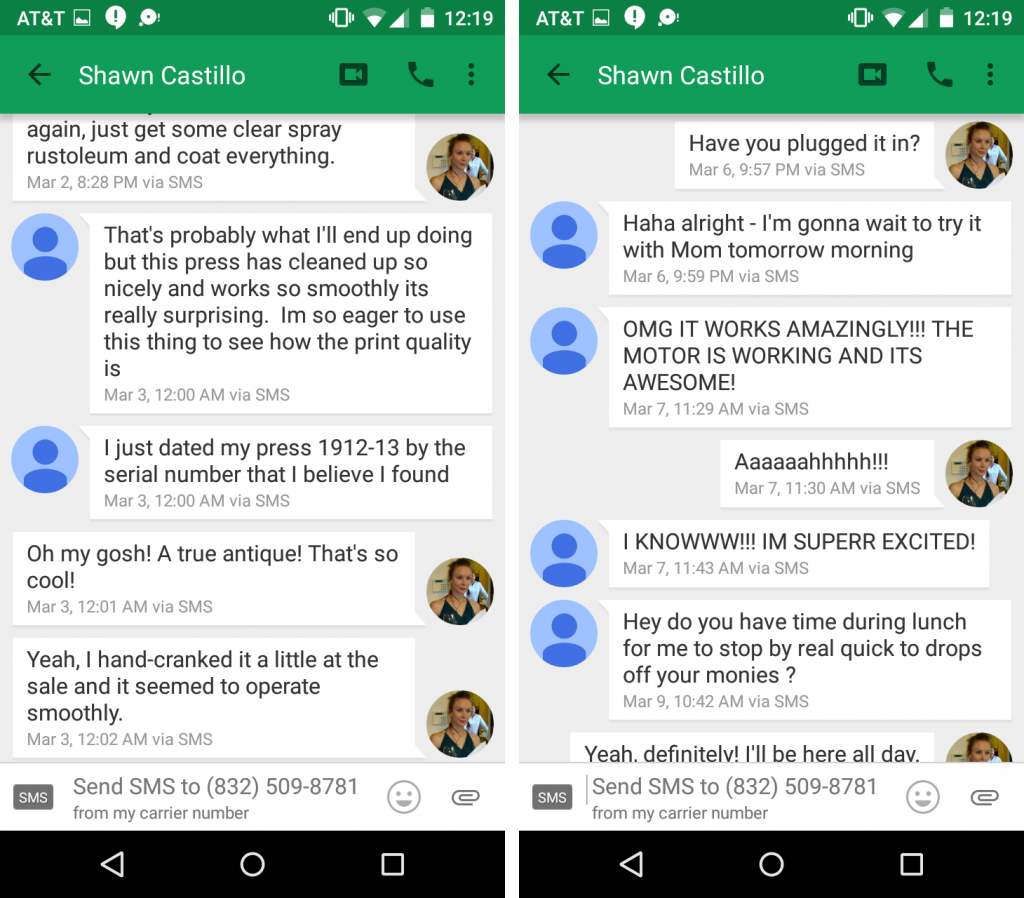

After getting it moved to my garage, I was able to fully examine it. There were some rust spots, but overall it was in good shape, and the wheel turned smoothly when I hand-cranked it. In spite of its good condition, it still took me about two months to clean the whole thing. It was a great surprise when I finally plugged it in and the 100-year old electric motor came to life with a startling puff of smoke. I guess they built things to last back in the day. After the cleanup, I still had to hunt down a lot of parts that needed replacing.

The letterpress is a 1912-1913 Chandler & Price 8 x 12” letterpress with an electric motor attachment. The rollers had deteriorated, but all four metal chases and two quoins (coins) were in good shape, plus I inherited a handful of type letters that comprised a business card the previous owner had left in one of the chases.

To round out my new print shop, however, I had to hunt through a lot of websites to collect the remaining items, like new rollers, ink, and type. I became an eBay addict, bidding on all sorts of antique and rebuilt bits and pieces. It took me another two months to get everything else I would need to actually print my first project.

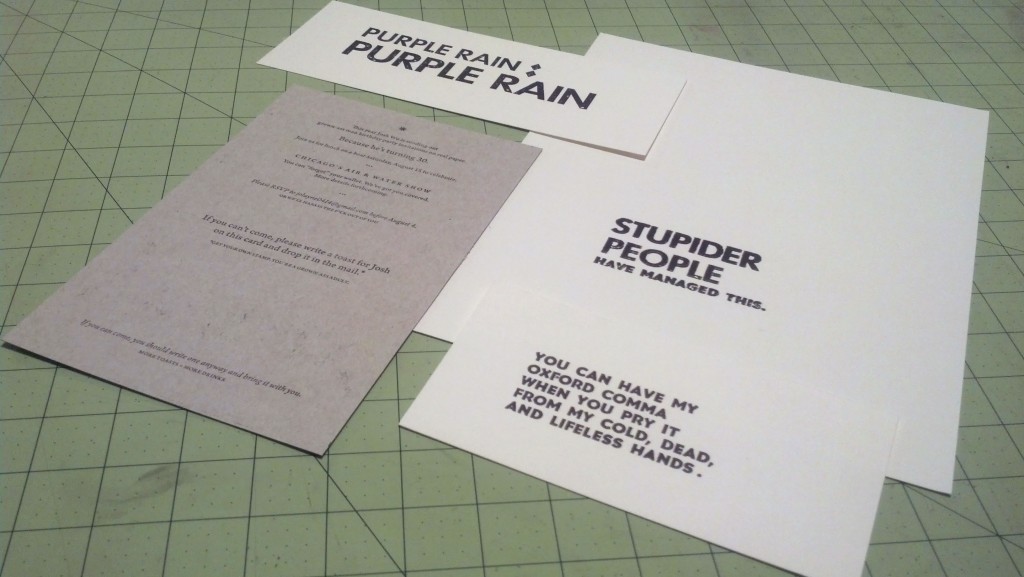

Shawn: The first time I actually got to print was with Jo when she made a visit to see the cleaned up press in all its glory. We didn’t really have a plan for what we were printing, but the impromptu project Jo came up with was the perfect thing for our first attempt at using a vintage letterpress.

Jo: I finally got to visit the press and have a work day once Shawn got it up and running. In honor of our (nearly) complete ignorance of how to use one, I decided to typeset and print something I always say to myself whenever I’m trying to learn something new:

“Stupider people have managed this.”

I chose Berthold Akzidenz Grotesk, Bold, all caps, 24-pt. lead type for the first two words and used 18 pt. bold lowercase for the remainder. We ran a small run of about 80 prints, troubleshooting as we went and getting many of them a little crooked or with the ink a little too globby. Basically, success.

Shawn: This whole experience of buying a letterpress has been surreal. I sometimes still can’t believe that I actually own one. It’s great to have this capability at my fingertips. I’ve since printed a few more small personal projects with friends, and I’m still continuing to learn all the little intricacies involved with this old-fashioned style of printing, in addition to the nuances of my own press.

Resources:

Estatesales.net

Sign up to be notified via email of weekly estate sales in your zip code, along with addresses and photos. This is how we found the press for sale!

Printingmuseum.org

A hidden gem of a museum right here in Houston offering printing and bookmaking workshops and programming.

Toddspresstime.com

New rollers cost between $110–140 each, and my press needs four of them. They also refurbish old rollers for half the price.

Arionpress.com/mandh

These guys have an extensive list of available typefaces to choose from, and seem to be very reasonable on price.

Letterpressplates.com/bases-supplies

Bases are used with polymer plates, which is how many currently operating press shops print without having to use lead type.

BriarPress.org

This is a great resource for all things letterpress, and for connecting with other letterpress owners and enthusiasts. All my “how-to” lessons came from this site.